CNC Simulator Software Based

PECO CNC Simulator, is not just a simulator it is integrated software package that includes:

1.G-Code parser and debugger with advanced features like canned cycles

and macros.

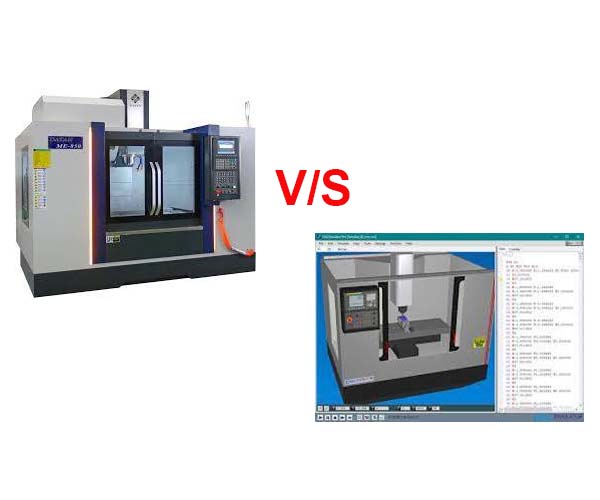

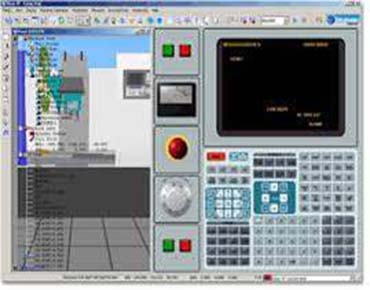

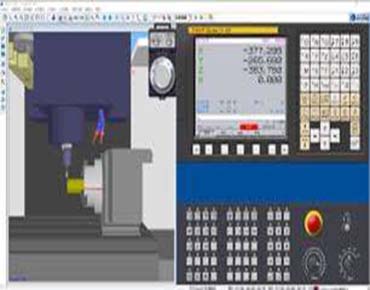

2. Realistic CNC machine simulator. Setup, program and operate various CNC machines in a virtual safe environment.

3. Server module to manage student’s access to the system, provide remote

assistance and administer tests.

4. PECO CNC Simulator Software has a feature of ‘’Multimedia Teachware’’ in the help menu, with help of this great feature student learns machine construction, machining operations, tooling, work holding and programming.

The 3D Models Machines can be customized for Customer

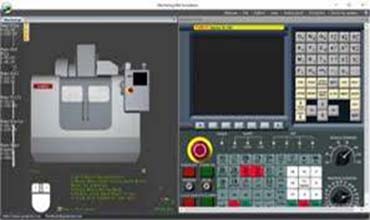

Real Machine CNC Control Panel

Virtual CNC Control Panel

PECO CNC simulation software can detect and correct any errors or collisions in your CNC code, such as wrong tool paths, incorrect parameters, or incompatible fixtures.

PECO CNC simulator software enables a trainee to learn machine operation without an actual machine. Trainees can safely and efficiently practice machine operating skills on a PC, and get ready to operate real CNC machines in a very short time.

Virtual CNC Milling & CNC Lathe In one Package

Technical Features

Support licenses are available in different formats 2,2.5,3 axis and 5 Axis CNC Virtual Software.

Contains 65 systems and 119 control panels (more being added)

Rendeing using OpenGL for fast and accurate 3D modelling.

Realtime dymanic rotation, zooming, panning and switch views.

G-code parser with code validaton supports G-codes and M-codes

G-code debugging tool

Capabily to simulate canned cycles, macros and the inclusion of parameters.

Fanuc, Siemens polar coordinate programming, G02, G03 spiral interpolation

Support for custom codes and cycles in different NC systems

Simulates post-processed files from UGS, Pro-E and masterCAM

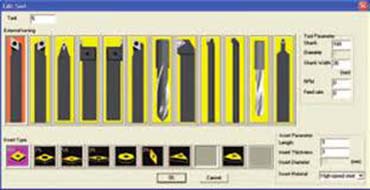

Materials library, edit and insert niew materials.

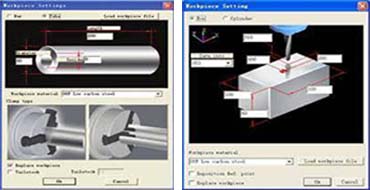

Worpiece setting and mounting.

Database management tools and tools customization

Turret can be configured for 4, 8, 12 tools. The ATC can be horizontal/vertical

Measuring tools: edge finger, feeler gauge, micrometers, calipers, etc

Roughness measurements based on cutting parameters.

Machine simulation includes like coolant, sound for machining operations and chips generation

Automatic updates online

Operation process recording and reply in AVI format And much, much more

LEARN MOST POPULAR CNC CONTROL PANEL IN INDIAN INDUSTRIES.

MANY SERIES OF FANUC FAMILY TURN & MILL CONTROL PANELS

MANY SERIES OF (SIEMENS) SINUMERIK TURN & MILL CONTROL PANELS

HEIDENHAIN CONTROL PANELS

HAAS CONTROL PANELS

MITSUBISHI CONTROL PANELS

5 AXIS VIRTUAL CONTROL PANELSOFTWARE ARE ALSO AVAILABLE

CUTTING TOOL’S LIBRARY & G-CODE SIMULATOR SOFTWARE

MORE THEN 100 VIRTUAL CNC CONTROL PANELS

LATHE CUTTING TOOL MANAGEMENT

MILLING CUTTING TOOL MANAGEMENT

CNC G-CODES SUPPORTED IN LATHE & MILLING